How a Small Town Entrepreneur Turned Used PET Bottles into a Rs 80 Crore Turnover Business and a T-Shirt Brand

Shyla F

|

08-June-2024

Vol 15 | Issue 23

Achieving success in business demands a lot of hard work and sacrifice, especially for first-generation entrepreneurs.

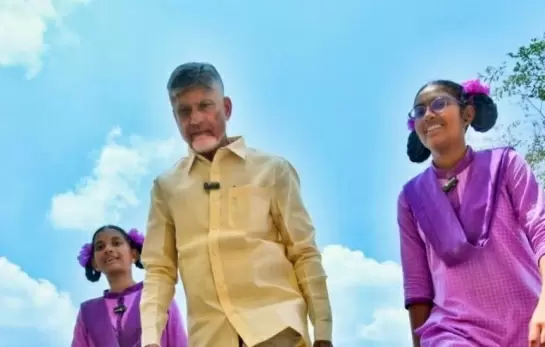

Senthil Sankar, a young man from Tamil Nadu, joined his father's fledgling business in a Tier-III city and has steadily built it into a company with a turnover of Rs 80 crore.

What's even more impressive is that he has created a sustainable clothing brand called Ecoline, using fabric made from recycled PET bottles.

| Senthil Sankar joined his father's fledgling recycling business leaving his lucrative job (Photos: Special Arrangement) |

His father, Sankar K, always had a passion for sustainable businesses, even decades ago when the concept wasn't widely known.

He started a nylon recycling business in 1992 but later shut it down and moved to Dubai to work for a company named Solid Surface, which made synthetic marbles.

In 2008, Sankar founded Shree Renga Polymers in Karur, a small town in Tamil Nadu about 80 km from Trichy, with an investment of Rs. 23 lakh.

Senthil joined the company in 2011, even though his father wanted him to find a job abroad and settle there. However, Senthil was against the brain drain and wanted to contribute to his own country.

"I wanted to pursue entrepreneurship despite having a good job with TCS and an offer from Silicon Valley. Because I believe that entrepreneurs and good companies drive the economy," says Senthil, now 38, a B.Tech Mechanical Engineering graduate from VIT Vellore.

"I was inspired by the Bollywood film 'Guru,' based on the life of the founder of Reliance Industries, Dhirubhai Ambani. I watched it many times, and it made a lasting impression on me.

| Shree Renga Polymers was making plastic flakes from PET bottles when Senthil joined the company |

"When I told my father that I wanted to quit my job and join him, there was a lot of debate at home. He never wanted me to settle in a small place like Karur. But I liked Karur a lot and was drawn to the entrepreneurship zeal, hard work, and the spirit of enterprise of the people there."

When he joined the company, the production capacity of plastic flakes was 300 tons. By 2014, it went up to 600 tons, and they were exporting to China, Sri Lanka, and the US.

In 2014, they transitioned from producing flakes to polyester fibre, which was also made from PET bottles. A year later, the company embraced the colour master batch technique, a method that dyes plain white fibre in various colours without using water.

This sustainable technique helps reduce environmental concerns associated with textile dyeing, which often pollutes water bodies.

The father-son duo took a loan of Rs. 1 crore from a bank to buy a second-hand colour master batch machine. Unfortunately, the expected returns did not come, leading to a tough financial situation.

Both his father and mother, Vijayalakshmi, who too was by this time involved in the business, had to return to work. Both parents, graduates from IIT, had enjoyed successful careers.

"My parents had to go back to college to teach and earn for the family because we needed to pay back the loans. There came a point when we were discussing within the family that business is not our cup of tea," says Senthil.

| Senthil with his dad and mentor Sankar K |

“However, thankfully, by 2017, the market improved, and our product gained recognition. Our situation finally improved, and we were able to repay the loans.”

The company kept evolving. Starting with manufacturing plastic flakes by recycling PET bottles, they moved to making polyester fibre, then to producing yarn from the same raw material, and finally to creating their own clothing brand.

Initially, they started their sustainable clothing business from Karur Textile Park with 250 women in 2018, and were only manufacturing T-shirts for local and regional clients. Later, they expanded the business to manufacture for well-known brands like Jockey and Van Heusen. No retail stores or online business were required to sell the product.

In 2020, they decided to take their sustainable product to the customer under their own brand name, Ecoline. They faced several challenges initially, but quickly developed the business with support from corporate companies that began to buy their products.

“It took us time to make people understand that this garment is made from recycled PET bottles. For this, we exposed our entire making process in a video form on our website to educate the customer,” says Senthil.

“It took time to convince people. In the meantime, corporate companies started supporting the eco-friendly approach towards various things and our product became a good fit for it.

“Many companies like Indian Oil, Saint Gobain, India Cements, TVS, Ramco, BMW, Zoho, and Infosys started approaching us about these T-shirts for their employees, families, and corporate events.”

Ecoline is now recycling 15 lakh PET bottles per day. If these bottles were left as they are, they would cover the area of a football field or end up in landfills. Each T-shirt from Ecoline prevents 5 kgs of CO2 emissions.

| Senthil and his father ensure that nothing goes waste in the company |

The company has saved 0.75 TMC (thousand million cubic feet) of water to date, which is enough to fill the entire Veeranam Lake in the Cuddalore district of Tamil Nadu. They have recycled 1,64,250 tons of PET bottles since their inception and have prevented 10,600 tons of CO2 emissions.

Importantly, the company does not use coal to run their factories. They rely on 90% solar and wind energy for production and 5-10% of the government supply.

The company has also come up with a buyback program for their garments. If someone gets bored of wearing the same piece of clothing for four or five years, they have the option to send the product back to the company. The company will recycle the product into a new one.

“And even if people don’t send the product for recycling and it ends up in landfills, it is 100% biodegradable,” says Senthil.

The father-son duo ensures that nothing goes to waste. They utilise every by-product from the factory. For example, they use firewood for the boiler, converting it to ash, which is mixed with mud to make pavement blocks for their own factory.

Ecoline generates 30 tons of fibre per day from PET bottles and manufactures 30-40,000 garments every month from it, apart from selling the fibre to major global players in Australia, New Zealand, and Sri Lanka and various corporations in India.

Out of the entire business of Shree Renga Polymers, fibre and yarn account for 85% of their revenue, while the clothing range Ecoline accounts for 15%.

| Sankar had tried his hand in the recycling business even way back in the 1990s |

They have around 120 SKUs in the clothing range, making T-shirts, jackets, athleisure, activewear, blazers, stoles, towels, pouches, shawls, laptop bags, tote bags, and shopping bags.

The minimum-priced product at Ecoline is a T-shirt for Rs. 299, and the highest-priced product is a blazer that costs Rs. 6500.

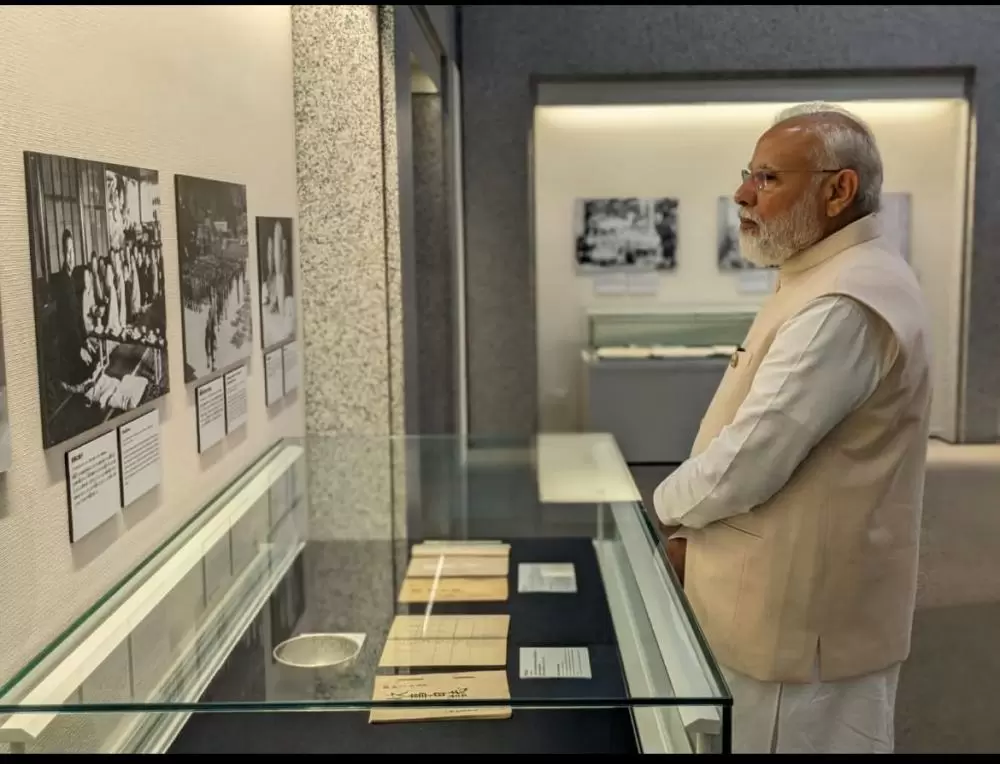

Ecoline jackets have been worn by many VIPs and celebrities, including Prime Minister Narendra Modi. "He wore them at the G20 summit held in New Delhi and at the White House in the US," says Senthil.

The company has hired a fashion designer from NIFT Chennai to design the clothes. They have around 450 employees who look after recycling, manufacturing, branding, and everything else.

Senthil has also invested in about 35 start-ups in addition to his own business. While he is not actively involved in these firms, he looks after their strategy.

On the personal front, Senthil is married to Jayashree Senthil, a criminal lawyer who handles the legal, administrative, and CSR aspects of the company. The couple has two sons, Jayant, 11, and Lingesh, 6.

| Prime Minister Narendra Modi wearing one of Ecoline jackets |

In his leisure time, Senthil enjoys learning and reading about new ventures. "Never stop learning" is his mantra, and he reads a lot of books to stay updated.

His advice to upcoming entrepreneurs is, "It takes not less than 1000 days to understand your business, your product, or your customer. So give the due time to your business. Persistence is also crucial. Never try to fool the investors because if you are doing it, you are eventually fooling yourself." - ©TWL